Articles

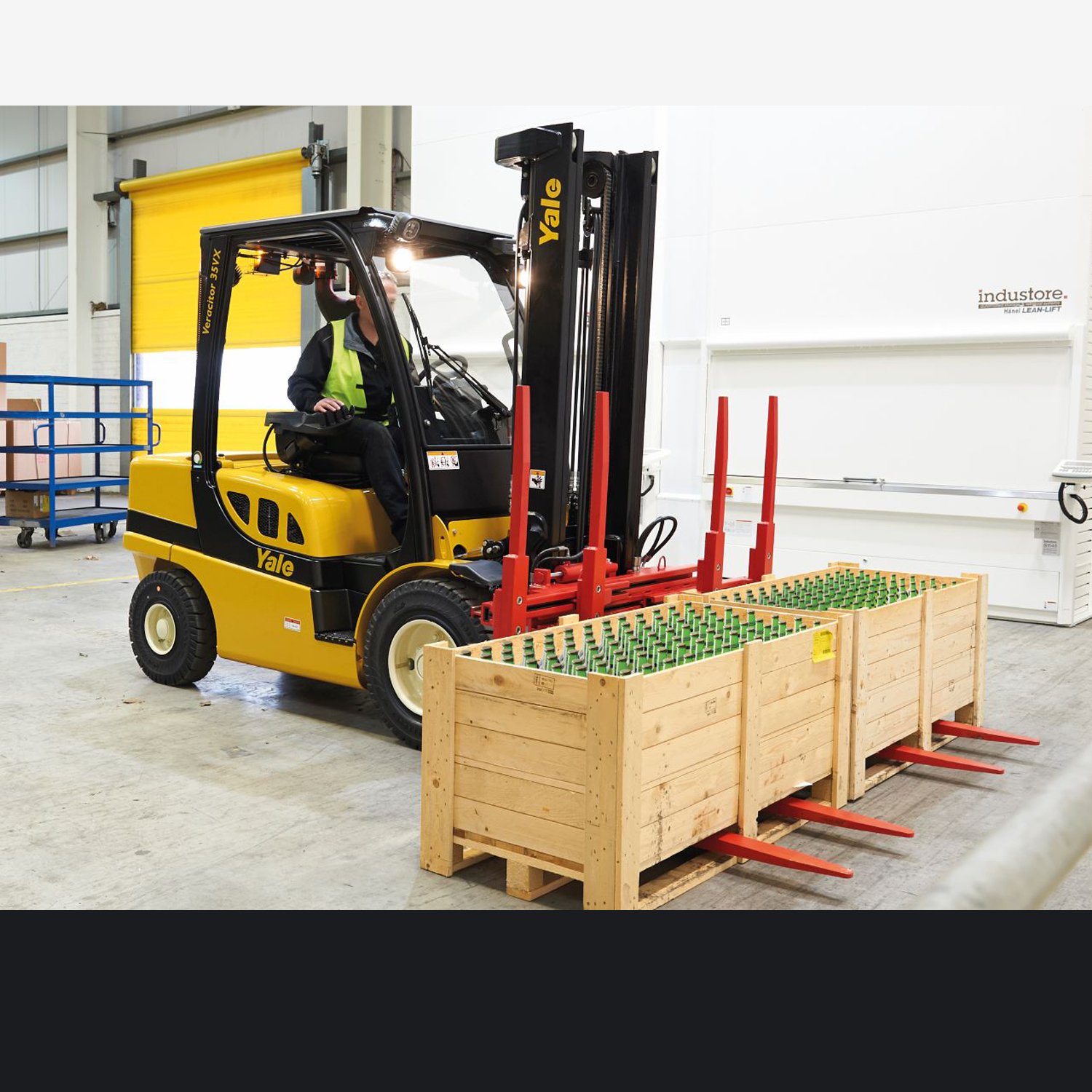

Forklift plays a crucial role in warehouse operations, facilitating the movement and transportation of heavy loads with ease and efficiency. These powerful machines are designed to handle a wide range of materials, from pallets and crates to machinery and equipment. Forklifts, equipped with lifting forks or attachments, are indispensable in logistics and supply chains. Operated by trained professionals who adhere to strict safety protocols, they minimize accidents and damage. Forklifts excel in productivity, speed, and precision, making them essential in modern warehouse management. They handle various tasks, including loading/unloading, pallet transportation, and inventory organization. By utilizing forklifts, companies streamline operations, reduce manual labor, and enhance productivity.

Types of Forklifts and Their Features

Forklifts come in various types, each designed to cater to specific warehouse needs. The most common types include electric forklifts, diesel forklifts, and propane forklifts. Electric forklifts are known for their quiet operation, zero emissions, and suitability for indoor use. Diesel forklifts are ideal for outdoor applications due to their robustness and higher lifting capacities. Propane forklifts offer versatility, with the ability to work both indoors and outdoors. Additionally, forklifts are equipped with features such as adjustable forks, mast tilt, and side-shift capabilities, allowing operators to customize their lifting and stacking operations.

- Counterbalance forklifts: Counterbalance forklifts are the most commonly used type of forklift in warehouse operations. A weight-bearing counterbalance offsets the weight of the lifted load at the front of the truck. This design eliminates the need for additional support, allowing the forklift to maneuver efficiently in tight spaces. Operators power counterbalance forklifts with electricity, diesel, or gas, providing flexibility for indoor and outdoor use. They lift between 1 to 8 tons and feature cushion or pneumatic tires depending on the application.

Benefits of Utilizing a Forklift in Warehouse Operations

Incorporating forklifts into warehouse operations brings numerous advantages. Firstly, forklifts significantly enhance efficiency by reducing the time and effort required for manual handling tasks. With their ability to lift heavy loads, forklifts enable faster loading and unloading, minimizing downtime. Moreover, the maneuverability of forklifts allows for efficient use of limited warehouse space, enabling high-density storage and maximizing storage capacity. By utilizing forklifts, companies can also ensure the safety of their employees. as the machines are equipped with safety features like seat belts, overhead guards, and rearview mirrors.

Factors to Consider When Choosing The Forklift for a Warehouse

When selecting a forklift for warehouse operations, several factors need to be taken into account. These include the required lifting capacity, the height of the racking system, the aisle width, and the type of load being handled. It is essential to choose a forklift with the appropriate specifications to ensure it can perform the necessary tasks efficiently. Additionally, considering factors such as maintenance requirements, fuel type, and ergonomic features will contribute to the long-term effectiveness and cost-efficiency of the forklift.

Maintaining Forklifts for Optimal Performance

Proper maintenance of forklifts is crucial for their optimal performance and longevity. Regular inspections, including checking fluid levels, tire pressure, and brakes, are essential to identify and address any potential issues promptly. Regular maintenance, following manufacturer recommendations, and conducting routine tasks like oil changes and filter replacements are crucial. Operator training ensures forklift efficiency and longevity.

Material Handling Manufacturers: Enhancing Efficiency and Productivity

Material handling plays a crucial role in various industries, enabling the smooth flow of goods, optimizing efficiency, and enhancing productivity. As businesses strive to streamline their operations, the demand for reliable material handling solutions has increased significantly. In this article, we will explore the importance of material handling and shed light on reputable material handling manufacturers that specialize in delivering top-notch equipment and systems.

The Significance of Material Handling:

Effective material handling is vital for businesses to ensure the seamless movement, storage, and control of materials throughout their operations. Also, It encompasses a wide range of activities, including transportation, storage, picking, packaging, and distribution. By implementing efficient material handling practices, companies can minimize production delays, reduce inventory costs, prevent damage to goods, and enhance overall operational efficiency.

Conclusion

Forklifts play a vital role in enhancing warehouse operations by streamlining material handling processes, improving efficiency, and ensuring the smooth flow of goods. With their versatility and lifting capabilities, forklifts have become an integral part of modern warehouses.

By selecting the right type of forklift, considering specific warehouse requirements, and implementing proper maintenance practices.